Direct-to-Fabric Dye Sublimation: The Future of Textile Printing

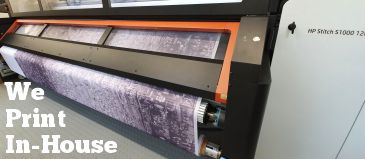

Direct-to-Fabric Dye Sublimation (DTFDS) is an innovative printing process that combines precision, efficiency, and vibrant color reproduction for textile industries. Unlike traditional printing methods, DTFDS allows for the direct transfer of designs onto fabrics, creating vivid, durable prints that are perfect for fashion, sportswear, and home textiles.

What is Direct-to-Fabric Dye Sublimation?

DTFDS is a digital printing process where designs are directly printed onto fabric using sublimation ink. The ink is transferred to the fabric in a gas form, allowing it to bond with the fibers of synthetic fabrics (like polyester), creating long-lasting, full-color prints. This is achieved using a heat press, which sublimates the ink onto the fabric, turning it into a gas that penetrates the fibers.

The Process

- Design Creation: The process begins with designing artwork on a computer. This digital file is prepared for printing, often using graphic design software.

- Printing: The design is then printed onto a special transfer paper using sublimation inks. The ink is in liquid form and, once printed, is ready for heat transfer.

- Heat Transfer: The printed transfer paper is aligned with the fabric. Using heat (usually around 400°F or 200°C) and pressure, the ink on the paper sublimates—turning from a solid to a gas. The gas then bonds with the fibers of the fabric, creating a permanent print.

- Cooling and Finishing: After the transfer process, the fabric is cooled and ready for use. The fabric’s colors are vibrant, durable, and won’t fade easily even after washing.

Advantages of Direct-to-Fabric Dye Sublimation

- Vibrant Colors: The process allows for full-color, high-resolution prints that are sharp and eye-catching.

- Durability: Since the ink bonds directly with the fibers, the prints are long-lasting and resistant to fading, even in high-wash conditions.

- Eco-Friendly: Dye sublimation printing produces minimal waste and uses water-based inks, making it a more environmentally friendly option compared to other printing methods.

- Soft to the Touch: Unlike screen printing or other techniques, the ink becomes part of the fabric, meaning there’s no raised surface—just soft, breathable material.

Limitations

However, DTFDS has its limitations. It works best on synthetic fabrics, such as polyester, and not on natural fibers like cotton. Additionally, while the process is efficient, it requires specialized equipment, making the initial investment higher compared to traditional methods.

Conclusion

Direct-to-Fabric Dye Sublimation is revolutionizing the textile printing industry by delivering high-quality, vibrant prints with excellent durability. Whether for fashion, sportswear, or home decor, this technology offers a modern, eco-friendly alternative to traditional printing methods, making it a popular choice for designers and manufacturers worldwide.